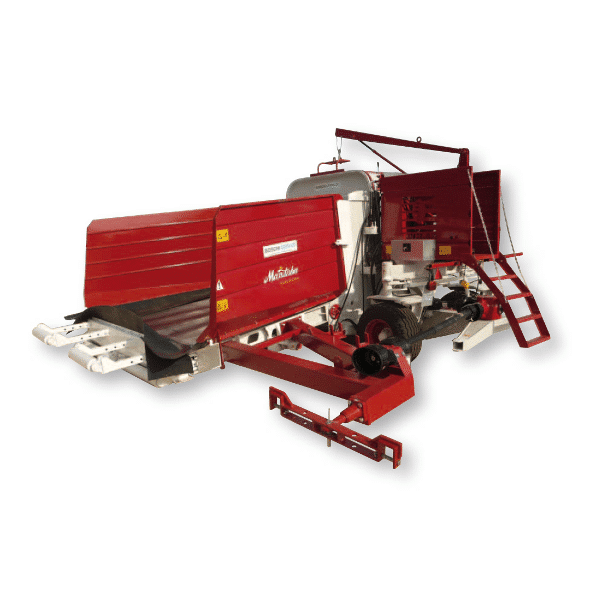

Manitoba Ensiler Evolution

Already many biogas stations in fact, trust in silobag system storage and Manitoba E.E. (with its characteristics) reflects the experience of years to maximize the success of this choice.

The main innovations are:

– the pressure of the product in the silobag is due to an inner braking device with double disk brakes, hydraulically driven by the inner brake system, and to four brakes on the wheels.

– The small size Back-stop is connected with one steel cable with high strength. This innovative system, one of a kind, allows putting the machine into operation in a short time and with an extreme facility.

– The transport takes place through a removable rudder and two rear wheels, making the machine easy to handle.

– Four-wheel steering hydraulically, to facilitate the adjustment of the steering during operation. The use of the four wheels and the only central cord reduces the overall dimensions of the machine allowing the positioning of four bags in the space previously occupied by three.

– The machine is equipped with a small crane with electric winch which facilitates the loading of the silobag on the machine, saving time and energy. Replacing the upper part of the tunnel can be installed the bags of 8-9-10 feet.

– Supply system with rubber tape of 10 mm thick, is hydraulically operated with variable speed controlled by a valve. Furthermore adopts a compression system consisting of three coordinated reels, with a new configuration which ensures increased productivity by 50%.

Also available in a motorized version and self-propelled version.

(*) Products that can be ensiled:

- corn silage;

- mash of grain;

- cereal fodder (barley, oat, triticale);

- grass crop;

- products of industrial process (beet pulp, fresh brewer’s spent grain, citrus pulp, olive pomace); etc..

Technical features:

Tunnel extension for 8 (2.44m), 9 (2.74m) and 10 (3.05m) feet

Minimum power: 100 kW/ 120 kW (130/160 hp)

PTO shaft speed: 1000 r.p.m

Indipendent hydraulic system

Braking system with double disk brakes with hydrauilc control

Central cable with lightened back-stop

Supply system with speed regolation

Storage capacity

The horizontal silobag can offer the following storage capacity (as a reference it is considered a product shredded with a specific weight of about 700 kg/mc):

- Ø8 feet (2.44m) of 60 m – 140 ton/silobag

- Ø8 feet (2.44m) of 75 m – 180 ton/silobag

- Ø9 feet (2.74m) of 60m – 175 ton/silobag

- Ø9 feet (2.74m) of 75m – 225 ton/silobag

- Ø10 feet (3.05m) of 60m – 215 ton/silobag

- Ø10 feet (3.05m) of 75m – 275 ton/silobag

Do you want more information?

OTHER PRODUCTS